Minimal Footprint Packaging...

The Era is Already Here!

Enhancing Packaging Efficiency While Maximizing Medical Device Protection

What is Minimal Footprint Packaging (MFP)?

Minimal Footprint Packaging (MFP) is a comprehensive approach to improving packaging outcomes. Several key criteria must be considered, but first and foremost is right-sizing the package. By utilizing the least amount of materials and reducing the package footprint, MFP ensures the highest level of protection while minimizing waste, resource consumption, and ensures transportation and shipping costs are minimized.

In addition to right-sizing, MFP takes into account factors such as shelf-life, seal integrity and ease of use. By optimizing these aspects, MFP enhances the overall efficiency and effectiveness of your packaging solutions.

Why is MFP Important?

In today's healthcare landscape, providing terminally sterile medical devices comes with numerous challenges. Packaging of devices can be expensive, time-consuming, and resource intensive. This is all reflected in the cost of goods, operating costs, logistics, and inventory management.

MFP addresses the costly and time-consuming aspects of packaging for OEMs, while also streamlining storage, clinical workflows, and waste disposal at user sites. Embracing MFP not only drives operational efficiency, it also contributes to a more environmentally responsible healthcare industry, benefiting all stakeholders.

MFP Defines CapSure

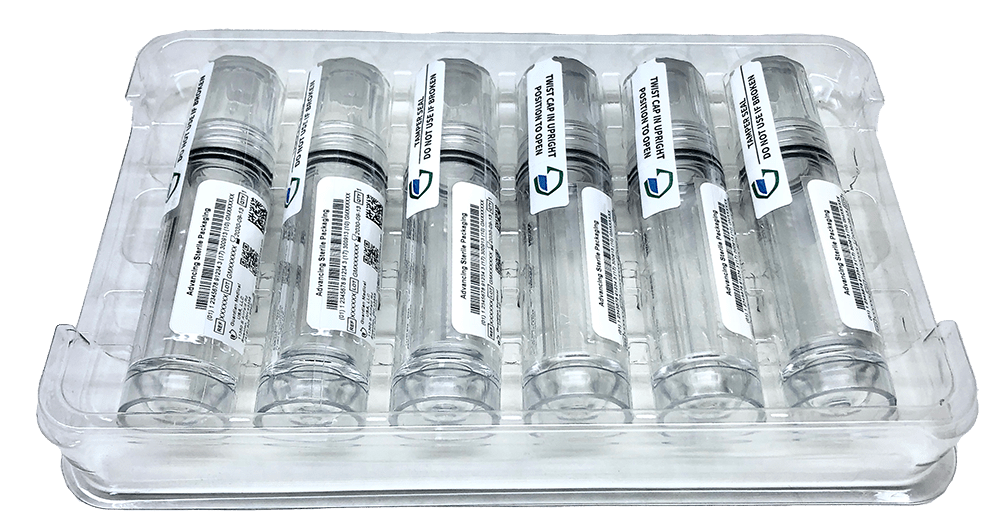

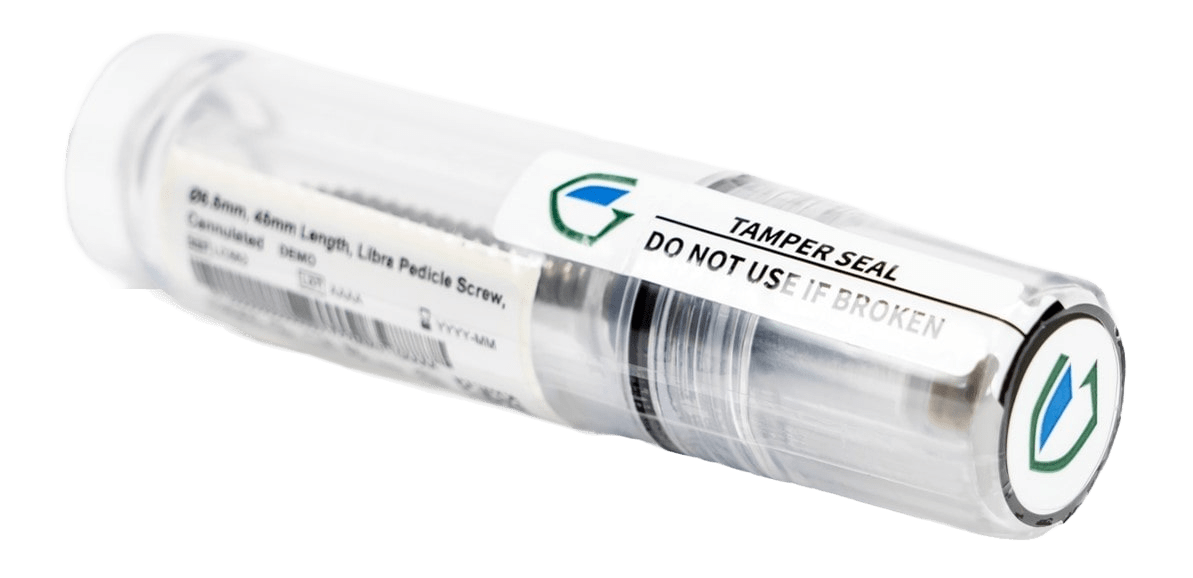

CapSure, our innovative Sterile Barrier Packaging System, perfectly complements MFP principles. First, we prioritize right-sizing the package. We achieve this by using a material that is highly impact resistant, offers exceptional clarity, and is recyclable. With our material, seal design, and unique nesting components, we offer single or dual barrier packaging solutions with fewer components compared to other packaging types. And, the CapSure packaging system has been pre-validated with a 10-year shelf life.

We have achieved an optimal balance between performance and price. CapSures unique design, combined with the advantages of MFP, streamlines your packaging process, reduces costs, and enhances product safety.

Advantages of MFP:

Unparalleled implant protection and size economy

Optimal Device Protection

Minimal footprint and requires no secondary packaging

Pre-validated with a 10-year shelf life

Made from Tritan, a recyclable material

With MFP, unnecessary packaging materials are eliminated, promoting environmental responsibility.

Choose Guardian Medical's MFP Solutions

Contact Guardian Medical today to learn more about right sizing your packaging with MFP!