In the ever-evolving landscape of medical technology, Guardian Medical stands out as a beacon of innovation. With its groundbreaking CapSure™ packaging, which is rapidly becoming a favorite within the medical packaging community, the company is redefining the standards for delivering medical devices to the surgical field.

We had the opportunity to speak with Tracy Momany, the President and CEO of Guardian Medical, about the benefits of CapSure™ compared to other packaging formats. Here's what we learned:

How does CapSure™optimize efficiency in the OR?

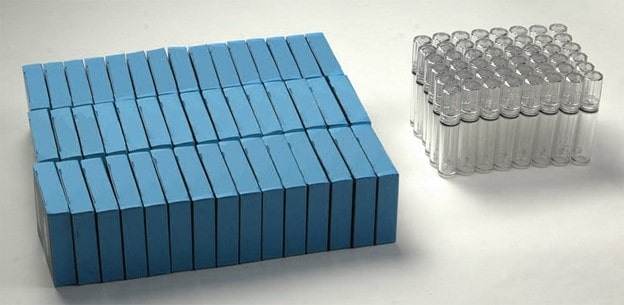

“The CapSure™ packaging system offers a minimal footprint, maximizing operating room organization and inventory accessibility. This efficiency is further enhanced by the system's color and size-coded tamper labels for rapid device identification. The transparent nature of the packaging allows for immediate verification of the implant, a feature not feasible with traditional packaging methods. Additionally, the intuitive unscrewing closure and design facilitate aseptic transfer to the sterile field, supporting the maintenance of strict asepsis protocols.”

What are the economic and environmental benefits of using CapSure™?

“The economic advantages of CapSure™are clear. Its impact-resistant design offers superior implant protection and eliminates the need for secondary packaging, reducing overall package size and associated costs. The minimal footprint packaging (MFP) technology significantly decreases expenses related to shipping, sterilization, and storage. The absence of Tyvek in our packaging sidesteps current supply issues, and the use of recyclable Tritan co-polyester material aligns with sustainability goals. The 10-year validated shelf life of CapSure™tubes mitigates inventory management concerns, minimizing the occurrence of expired product write-offs.”

How does CapSure™streamline new product launches?

“From an engineering perspective, CapSure™packaging simplifies the launch of new systems. The pre-validated seal design accelerates the validation process, omitting the need for aging studies. The ease of assembly and verification aligns with the demand for simplicity, speed, and quality assurance in the process of packaging medical devices. Notably, the packaging's design requires no sealing equipment or complex testing for seal verification, contributing to shorter lead times and reduced expenses for equipment procurement and validation. This efficiency facilitates rapid scaling of production and minimizes packaging lead times.”

Guardian Medical's CapSure™ tube packaging system presents a significant advancement in the delivery and management of medical devices within surgical environments. The design prioritizes efficiency, cost-effectiveness, and expedited execution, aligning with the medical device industry's needs to optimize its operations.

If you are seeking to improve operational efficiency, reduce costs, and maintain the highest standards of sterility, contact Guardian Medical to explore the integration of CapSure™ into your surgical supply chain: Contact The Guardian Medical Team